SCOPE

The information below outlines the options available for disposal of domestic wastewater in lieu of a sewer connection and looks briefly at the management implications.

In absence on any specific data on the house, its occupancy and use, site, soil conditions, adjacent water features, adjacent boreholes, local environmental authority requirements; the information below provides only basic details to identify the potential options for wastewater disposal and is not intended to be definitive.

All dimensions, volumes and distances are those that would be required in the UK, local requirements may be different, and should be determined by an appointed MEP engineer.

1. WASTE WATER TREATMENT OPTIONS

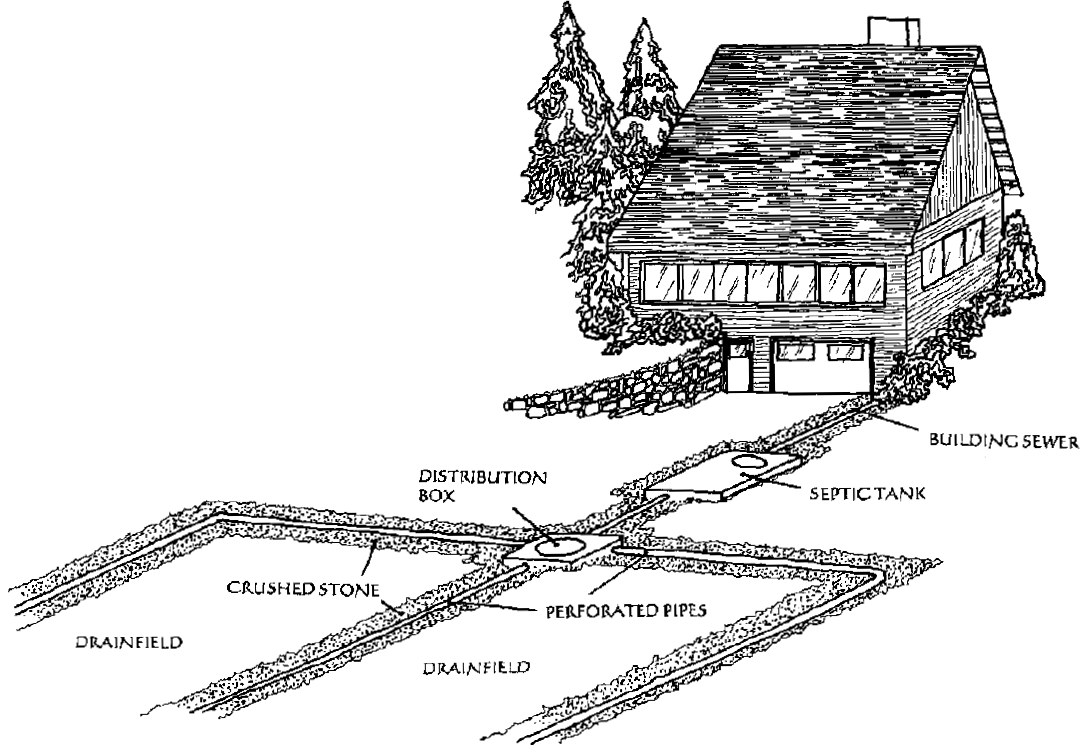

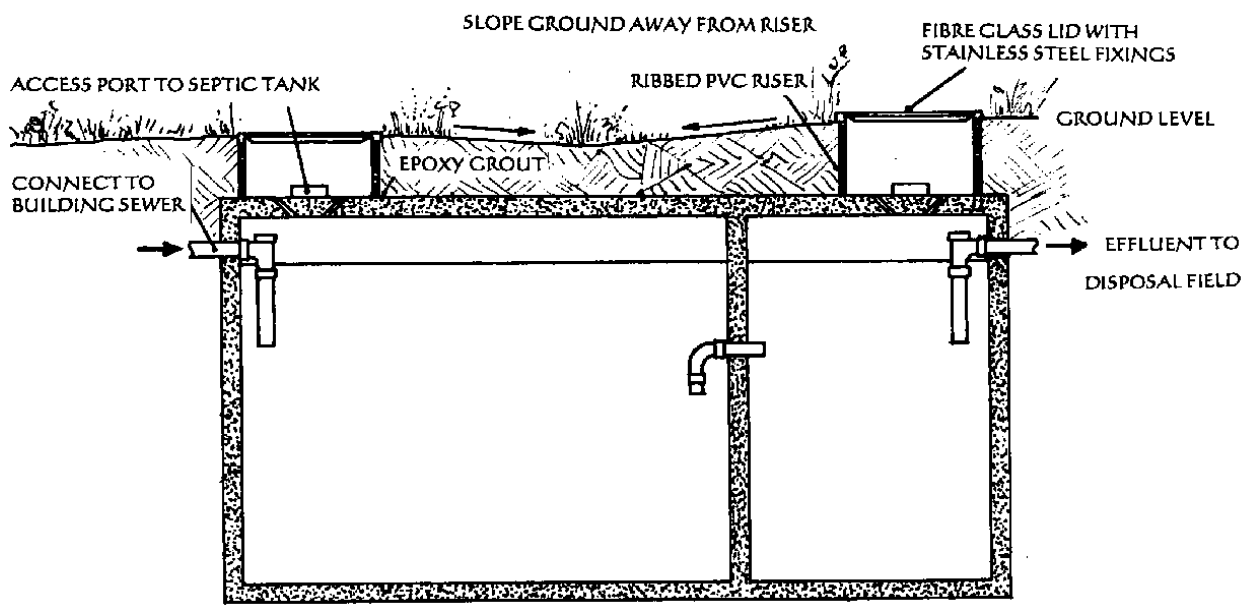

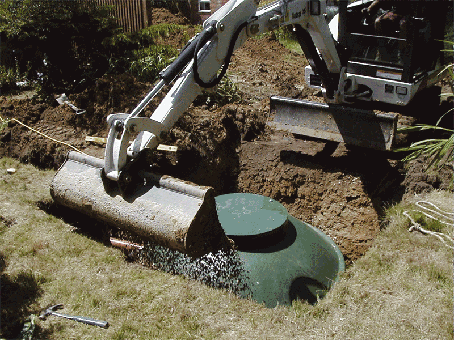

1.1. Septic tank

A septic tank is typically a two chambered, buried tank with an effluent outlet to a drainage field. The septic tank, usually made of concrete, is designed to be watertight. The principle of operation of a septic tank is that wastewater enters the tank first, where heavy solids sink to the bottom and grease and oils float to the top. The effluent passes from the first chamber to a second chamber, by gravity, where further settlement occurs. Most solids entering the septic tank settle to the bottom and are partially decomposed by anaerobic bacteria to form sludge. The effluent then passes in to a soakaway or a drainage field, where the majority of the treatment occurs. There should be no direct effluent discharge to watercourses.

A properly maintained septic tank keeps solids and grease from entering and clogging the drainfield, the land into which the tank overflows drain. To be effective, the soil must be suitable and undergo permeability tests, the result of which may be required to be submitted to the local environmental authority as part of the consent to discharge application. If the soil is not suitable, then the ground can become waterlogged and give rise to issues of odour.

Generally for a four person dwelling the septic tank would be of a minimum 2.7 m3 litres capacity, additional occupants would require the tank capacity to be increased by 180 litres per person. They need to be emptied on a regular basis, at least once per year. American case studies show tank capacity ranges from 4 m3 for a three bedroom single-family house, up to 15 m3.

1.2. Packaged Treatment Tank

Typically these are off the shelf plant, sized to match the expected effluent load and simply require installation and commissioning. Typical examples of packaged treatment plant are defined below.

Rotating Biological Contactor (RBC)

These are usually a single unit comprising of 3 chambers, the first stage being the primary settlement tank where the solids are settled out and retained as sludge. The partially treated effluent passes first to the anoxic and then the aerobic stage, where the secondary treatment occurs.

RBC’s generally protrude above ground and are therefore, visually intrusive. They require a power supply, although the motor is generally small as the speed required is between 2 and 4 rpm (revolutions per minute).

An RBC can tolerate some fluctuations in hydraulic and organic load but can suffer if there is a shock load. RBCs have no scope for adaption should the building change, i.e. if the wastewater flows are increased. The increase in flow will have to be accommodated within the plant or a new plant will be needed.

Overall, RBC’s are a simple and stable treatment process that has been proven over the years but are not ideally suited for single dwellings due to the relatively low flows they may receive.

Activated Sludge

An activated sludge plant uses the injection of air in to the wastewater to breakdown the organic load. The plant can be either two or three chambered units and with the air being bubbled up through the effluent from an aerator in the base. The process generates slurry which settles in the based and sludge is formed containing active microbes. Some of the sludge is re-circulated back in to the unit and retreated, keeping the units biomass active. The quality of the effluent can be very high and can provide some nutrient removal, such as nitrates. Similar to RBC’s, they can accept some load variations but not sudden shock loads.

Generally activated sludge plants are wholly buried and only the top is visible, so are therefore, visually unobtrusive. However, the air blower does need a surface mounted fan, which can give rise to aesthetic and noise issues. They do use more power than an RBC.

A variation of the activated sludge treatment is the sequencing batch reactor (SBR). The treatment occurs in a single chamber, where the blower is alternates between on and off, to allow the settling out of the sludge.

Packaged treatment plant general comments

Packaged treatment plant general comments

There are many types of packaged treatment plant available, all of which perform better with a constant flow of effluent, ensuring that the final effluent is treated to the correct standard. The local environmental authority may require the effluent quality to be monitored, to ensure the consent standard is not contravened.

In general, packaged plant are reliable and will, if maintained, provide years of service. They work best when there is a constant flow. If large variations in flow are expected, then precautionary measures, such as an additional balancing tank are required, to ensure the flow is kept at a constant rate.

Most types of packaged treatment plant hare the same following features:

- Off the shelf products but need careful selection to ensure the discharge consent will be met.

- Relatively compact and easy quick to install

- Easily maintained, by reputable manufacturers/installers who can offer maintenance contracts

- Relatively unobtrusive, as they are predominantly installed below ground

- Can achieve good quality effluent discharge and the effluent can be discharged direct in to a watercourse, if the correct discharge standard is met

- Relatively inexpensive.

However, they do have some disadvantages:

- They are not a do it yourself (DIY) item and do need specialist maintenance

- As they have mechanical and electrical components, they do wear out in time and will need replacement

- They do need de-sludging which, depending on the plant can be between 6 months and 2 years, depending on the plant and usage

- They require a power supply

- Will not provide any treatment in the event of a power outage or mechanical breakdown

- Can generate noise and occasionally odour problems.

1.3. Reed Beds

Vertical Flow Reed Beds

These work on a similar principal to traditional filter beds, where the effluent is spread over the top of the reed bed and allowed to pass vertically down through the filter media, generally gravel and sand as well as the rhizomes of the planting, to the outfall point. Organic matter can settle on the surface, which can give rise to some odour issues.

High levels of treatment are possible and so can be used to for secondary treatment, following a primary settlement tank such as a septic tank, but are generally used as tertiary treatment.

The effluent flow in to the reed bed can occur under gravity, providing there is sufficient hydraulic head, generally around 1.5 m from inlet to outlet, hence they do not necessarily require power.

They are easy to maintain as failure tends to be gradual and as such, preventative and remedial action can be carried out well in advance of total failure.

Visually, they can be very attractive and can provide a wildlife habitat.

Generally they require between 2 and 5 m² of land per person and can be quite expensive to install and can be sensitive to shock loads.

A Existing septic tank

B Pumping station (if required)

C Vertical reed-bed

D Pumping station

E Vertical flow reed-bed

F Humus Tank

G Balancing tank

H Horizontal reed-bed

J Flow control chamber

Horizontal Flow Reed Beds

Unlike the vertical flow reed bed, the flow occurs horizontally through the filter media. The air flow through the filter media is limited and so strong effluent can be poorly treated and potentially aerobic conditions can occur, giving rise to odour issues.

Similar to vertical flow reed beds, they are generally seen as a tertiary form of treatment but can be used for secondary treatment, following a septic tank. They require more land take than a vertical flow reed bed, between 5 and 10 m² per person, secondary treatment.

Although many consider that they are suitable for secondary treatment, there some who would suggest that they are really only suitable for tertiary treatment. Therefore, there is some confusion on their suitability.

Visually, they can be attractive and natural looking, be able to accommodate a wide range of plants. They can be cost effective, if installed as a DIY item, but again, the design needs to be considered very carefully.

As the flow is horizontal through the media, the media can become blocked and therefore needs careful maintenance. Normally, with good pre-treatment, the bed can be used for up to 10 years before the media and planting requires replacing and replanting.

General comment about reed beds

The main consideration for reed beds is the land available to accommodate them and do need regular maintenance, i.e. the reeds need to be harvested regularly and the waste material needs to be disposed of carefully, as the reeds accumulate toxins.

Also, the local MEP planners should consider the risk of freezing of the reed beds in case of very low temperatures.

1.4. Cess Pools

Cess pools are large sealed underground tanks where sewage is stored. The capacity of the cess pool below the inlet drain must be a minimum of 18,000 litres for 2 persons and must be increased by 6,800 litres for each additional user.

They need emptying on a regular basis, as they cannot be allowed to exceed their capacity. Generally, cess pools should be avoided, except where no other option is viable.